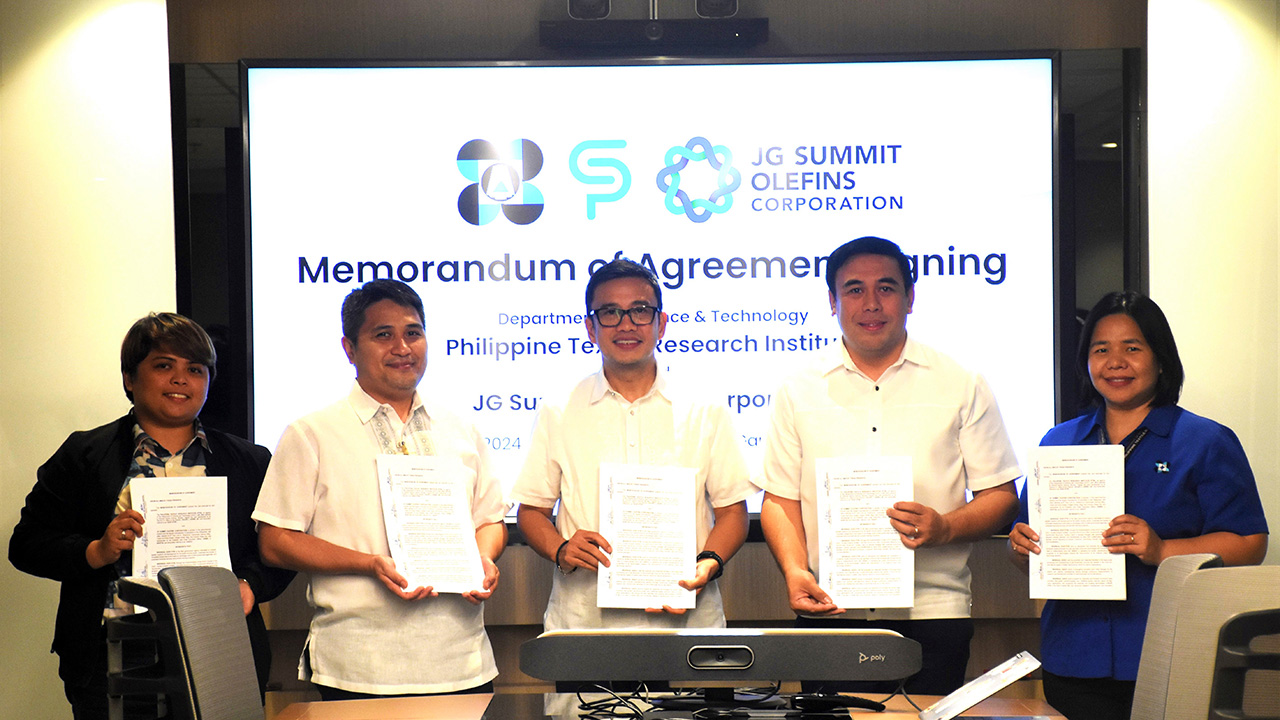

JG Summit Olefins Corporation (JGSOC) signed on June 18, 2024, a memorandum of agreement with the Philippine Textile Research Institute (PTRI) to collaborate on the “Spunlaid Nonwovens R&D: Sustainable Meltblown and Spunbonded Nonwoven Textiles” project.

A government agency under the Department of Science and Technology (DOST), the Philippine Textile Research Institute is dedicated to the research, development, and promotion of the country’s textile industry. Its R&D partnership with JGSOC is not only a key step toward strengthening and diversifying DOST-PTRI’s competency in nonwoven textile production, it also hopes to spur the local nonwoven fabric market by pursuing value-adding opportunities and partnerships.

“The project was borne out of the challenges with materials during the pandemic. With the inauguration of the first laboratory-scale meltblown line facility in the Philippines, we aim to broaden the scope of the Spunlaid Nonwoven Textile ecosystem. This is the first time that we are conducting research on polymers for textile application, and we are thrilled to partner with JG Summit Olefins Corporation for this project,” said Dr. Julius L. Leaño Jr., DOST-PTRI Director, at the MOA signing event.

“Innovation, research, and development are at the core of JGSOC's operations,” offered Arnel L. Santos, JGSOC President and CEO, regarding the company’s participation in the program. “Part of our mission is to contribute to nation-building and industrialization in the Philippines. So, it is encouraging to see collaborations with government agencies such as DOST-PTRI, which aim to help answer critical challenges faced by our fellow Filipinos through science and technology.”

The meltblown process and the spunbond process are the primary methods used in spunlaid nonwoven textile/fabric production.

In a meltblown line facility, polymers are heated above their melting temperature and the resulting molten material is extruded through small nozzles surrounded by gas blowing at high speed. The resulting fibers are collected to form a fabric.

The spunbond process, on the other hand, involves melting polymer granules and extruding them through spinnerets to create continuous filaments. These filaments are then cooled, stretched, and formed into a “web”, which is then bonded to create the final nonwoven fabric.

Spunlaid nonwoven textiles have many varied uses. In general, the fine fiber structure of meltblown fabrics is ideal for filtration applications, as well as for providing a barrier in medical and hygiene products. Spunbond fabrics, meanwhile, are regarded for their strength, durability, and uniformity. Suitable for applications requiring structural integrity, they are often used in medical products, packaging, agriculture, the automotive industry, construction, and many other industrial purposes.

For more information on JG Summit Olefins Corporation, visit jgspetrochem.com